Professional experience in:

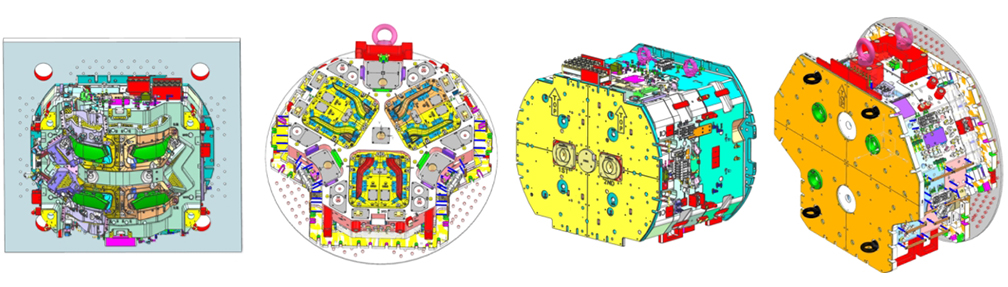

1. Auto lamp optical lightguide tool design

2. Auto lamp 2K/Multi-colour tool design

3. Auto lamp module lens tool design(under study

4. Air-assistance part tool design

5. Over-molding part tool design

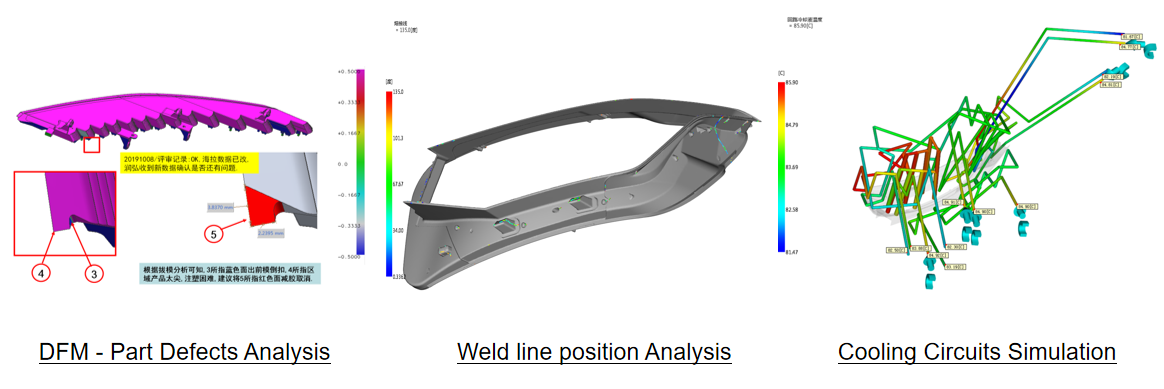

6. Part CAE / Moldflow analysis

7. Feasibility study for part structure & potential defects

8. Tool productivity evaluation analysis

9. Synconnize tool design along with customer R&D

10. Independent auto part design and development ability

Over decade’s rich experience specialized in auto lamp molds development

1. Headlamp 2K Outer Lens mold

2. Headlamp thick-wall light-guide mold

3. Headlamp multi-color Inner Lens mold

4. Headlamp 2K Bezel mold

5. Headlamp BMC mold

6. Rear Combination lamp multi-color Cover Lens mold

7. Rear Combination lamp multi-color Inner Lens mold

Rainbow establishes standard component and model database for tool design, also the database for lessen learn and success cases.

Success Case:

Problem Description: normally for this kinds of part, its production cycle time is about 60 seconds, which causes of high cost of production.

Reason Analysis: through investigation and analysis, there’s room of improvement and optimization for injection gate and cooling circuits for tool, which is based on Rainbow years of experience and previous lessen learn.

Action Implemented: adjusted injection gate with best position, and designed separate cooling channels for tool. Though there’s cost increased due to the milling difficulty enhanced. Yet it shorten the injection cycle time from 60s into 48s. Tool right now is running stably and smoothly without problem in Hella production plant. This is one of examples that Rainbow help our customers to save money as much as possible and support customer in our efforts to bring maximum profit.